In industrial field service, tracking every piece of equipment that makes a job possible is vital. From scissor lifts and welders to forklifts and specialized tools, these assets are expensive, mission-critical, and must be accounted for. When tracking is left to scattered spreadsheets, memory, or paper notes, crews risk losing equipment, missing billing opportunities, and facing customer disputes. The result is wasted money, wasted time, and frustrated clients.

Here’s why leading crane companies invest in proper equipment tracking, and why you should, too.

The Hidden Productivity Killers in Equipment Oversight

Without a centralized system, even minor oversights turn into major issues:

-

Invoices fall short because equipment used on the job wasn’t recorded

-

Rental equipment is returned late

-

Dispatch becomes guesswork when equipment availability isn’t instantly visible

-

Manual tracking leads to lack of visibility

These are more than annoyances. They’re operational gaps that damage trust, margins, and efficiency.

How crewOS Turns Chaos Into Clarity

At crewOS, we built equipment tracking to remove those gaps, because every piece of equipment used on a job must be billed and ready when it’s needed:

-

Accurate billing, guaranteed – Every tool and piece of equipment used on a job is recorded and factored into invoicing. No more surprise write-offs.

-

Prevent late rentals – Know who has what equipment, and when it’s due back, so delays don’t extend your costs.

-

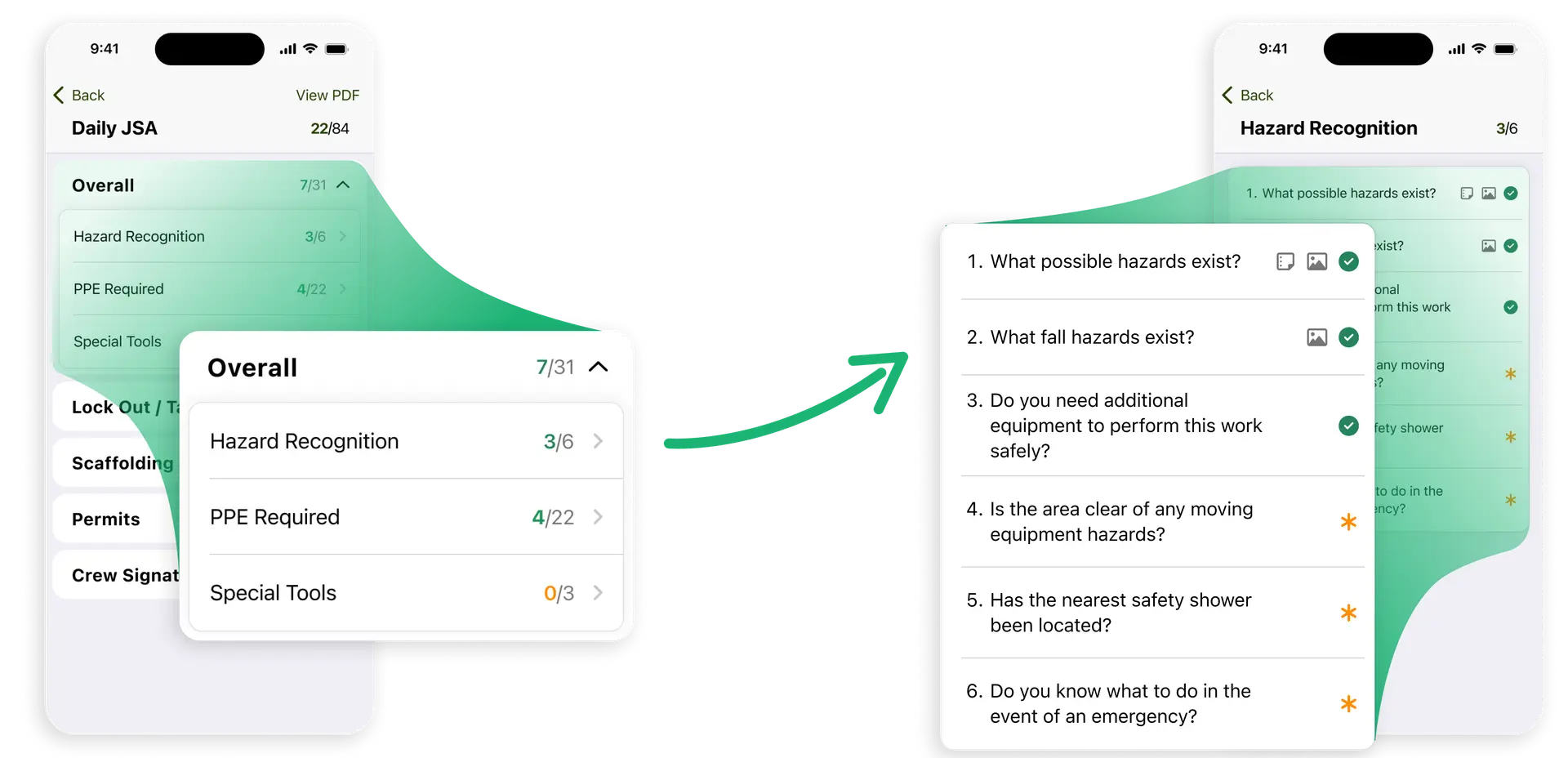

Track assets from anywhere – Use the mobile app to update equipment data in the field instantly, keeping your dashboard reliable.

-

Centralized oversight – Maintain full visibility over all equipment across crews and locations, even when schedules change or phones go offline.

The Underrated Power of Documentation

Consistent, real-time tracking of equipment, parts, and assets doesn’t just protect revenue, it strengthens accountability and trust. In a previous blog, we discuss the importance of capturing job details and proof in real time.

Equipment tracking is another critical layer. It ensures billing, maintenance, and availability all align with what actually happens on the ground.

From Risk to Reliability

Industrial field service is built on precision. Equipment not tracked is equipment that can fail, cost, or complicate a job down the line. Letting tools disappear into chaos creates friction that jobs, service teams, and customers can’t afford.

If your team is constantly chasing missing gear, delayed returns, or incomplete billing, your operations aren’t just inefficient, they’re vulnerable. The good news? crewOS can help.

Want to learn more?

It's Time To Get Started

We’ll help you be the hero every field service operation needs.