In industrial field service, checklists aren’t just a formality, they’re essential tools for accuracy, productivity, and compliance. But not all checklists are created equal. A one-size-fits-all form might work once, but it won’t adapt to unique equipment needs, inspection workflow, and more. That’s where crewOS Smart Lists come in—customizable, dynamic forms that match real-world tasks and deliver real results.

Why Custom Checklists Matter

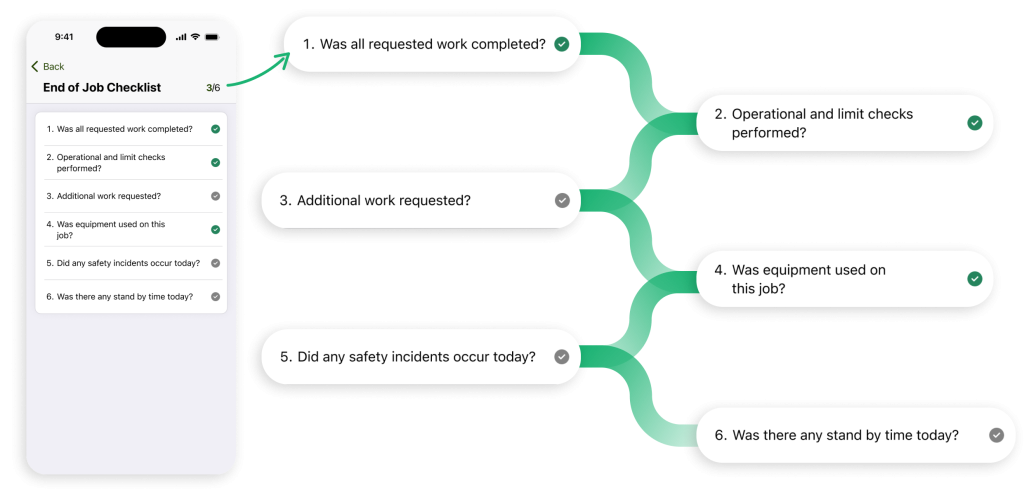

crewOS Smart Lists give industrial teams the power to define and enforce their own standard operating procedures—down to the task level. Whether it’s a maintenance workflow, equipment handoff, or end-of-day checklist, Smart Lists ensure that every team member follows the same expectations, every time. With custom fields and job-specific logic, you can build repeatable processes that reflect how your teams actually work, and hold them accountable for doing things the right way.

Smart Lists solve this by adapting to the context of each job.

Case 1: Job Scope & Task Accountability

When multiple crews are working across different sites, it’s easy for key tasks to fall through the cracks, especially when scope details are shared verbally or through generic documents.

Smart Lists let teams build task-specific checklists tied to each job, so nothing gets missed. For example, a service order involving a conveyor system might include:

- Confirm motor alignment

- Inspect belt tension

- Replace worn bearings

- Document serial numbers of parts replaced

Each task can require completion before moving to the next step, and photos or notes can be mandatory for high-impact work. This creates consistency across crews and clarity for office teams reviewing job progress.

The result: Everyone follows the same steps, expectations are clear, and accountability is built into the workflow. No more second-guessing or chasing down missing info.

Case 2: Streamlining Equipment Pre-Checks in the Field

Before dispatching generators, compressors, or cranes to remote sites, crews need to verify that everything’s ready to go:

- Fluid levels and filters

- Tire or track condition

- Battery and ignition

- Site-specific add-ons

With Smart Lists, a pre-check list can be created for each equipment type. A generator list might include voltage tests, while a crane checklist adds rigging gear inspection and hoist condition. Technicians can snap photos of any wear or missing parts, and “fail” entries can automatically trigger a request for supervisor approval.

The result: Equipment arrives ready, maintenance issues are caught early, and inspection records are logged in real time for management and auditing.

Case 3: Punch Lists & Quality Control

After completing a job, crews often walk through punch lists to capture minor issues like dents, loose bolts, wire clips, or signage placement. Smart Lists help here, too. You can:

- Create a “post-service punch list” template.

- Allow crews to tag items with photos and location notes.

- Let supervisors approve or escalate items in real time.

This gives office teams better visibility into what was found and fixed. It also keeps customers updated, showing attention to detail that reinforces trust.

The Smart Lists Advantage

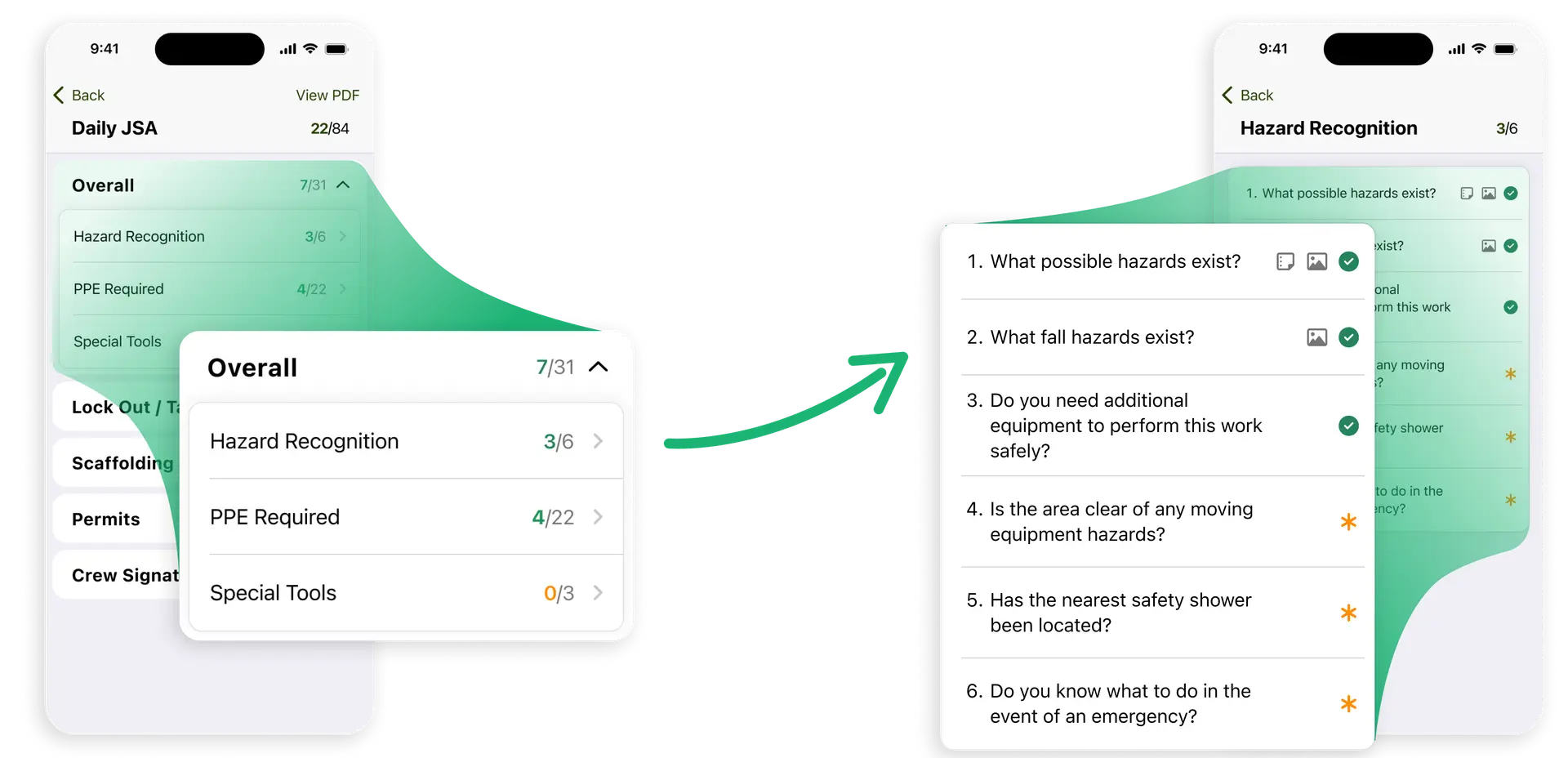

- Focused workflows: Each checklist is tailored to task, asset, or role—no more unnecessary sections.

- Reduced errors: Conditional fields and required photos prevent incomplete records.

- Faster documentation: Crews only see relevant questions, meaning less form fatigue and more accurate capture.

- Improved accountability: Timestamped entries and images back up that work was done properly.

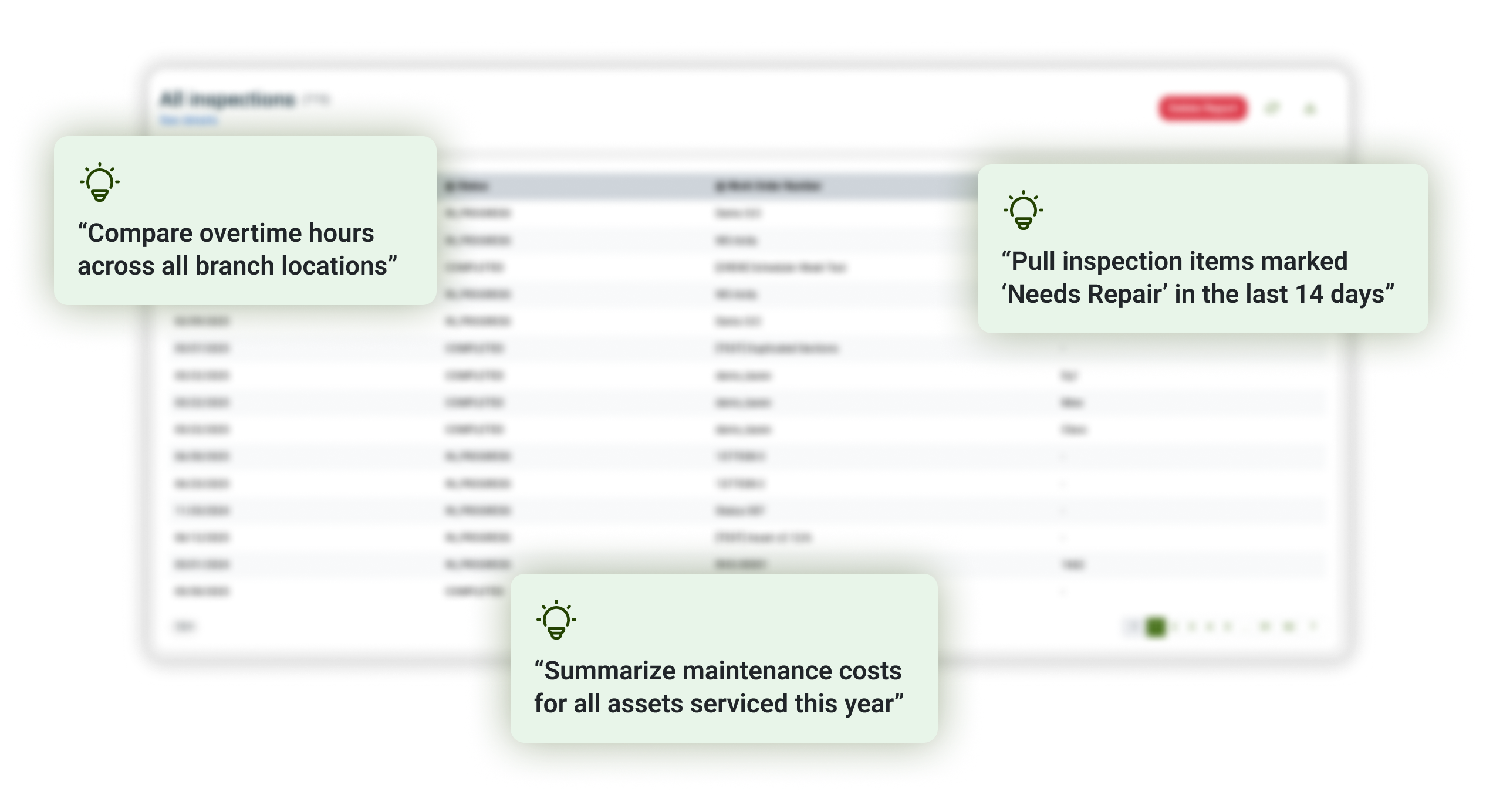

- Centralized insights: All checklists live in crewOS, accessible by managers, dispatch, compliance, and billing teams.

How It Works in crewOS

- Create Smart List templates via the web dashboard: designate fields, dropdowns, photo requirements, and conditional logic.

- Assign templates to jobs or roles: for a crane lift, a JSA-specific form loads automatically when the crew starts the task.

- Capture info on-site using the mobile app: choose the form, answer prompts, snap photos, add notes, then save.

- Sync in real time or offline: all entries are tagged to the job and crew and uploaded as soon as connectivity allows.

This consistent process means every form is job-appropriate, accurate, and available anytime someone needs to reference it.

Better Together: Documentation + Integrated Tools

Smart Lists gain power when paired with other crewOS features. For example, integrating checklists with Field Notes & Photos keeps records visual and contextual. Combining them with time tracking and scheduling turns documentation into part of a comprehensive workflow—one that helps field teams work smarter, not harder, by improving efficiency with integrated tools.

crewOS: A Smarter Way to Work

Smart Lists aren’t just checklists, they’re a smarter way to ensure consistency, accuracy, reduce risk, and boost accountability in complex field operations. By providing the right prompts at the right time, tailored to the job and the crew, documentation becomes actionable and trustworthy. And when field teams work smarter, the whole operation runs better.

Curious how Smart Lists can streamline your workflows?

It's Time To Get Started

We’ll help you be the hero every field service operation needs.