In industrial field service, inspections are the foundation of safety, compliance, and trust. Whether it’s a crane, a fan, a conveyor, or another mission-critical piece of equipment, inspections determine if assets can perform safely and reliably. Yet too many companies still rely on outdated, manual inspection processes, like paper checklists, spreadsheets, and disconnected tools, that leave room for error and slow down reporting.

That approach may have worked in the past, but today’s industrial environment demands more. Customers expect faster turnaround, regulators demand airtight records, and leadership needs insights that go beyond pass/fail checkboxes. Inspection software should rise to meet those needs, but not all platforms are created equal.

If you’re evaluating inspection tools for your operation, here are four must-have features to look for, and why they matter.

1. Standardized Templates for Consistency

One of the biggest challenges in industrial inspections is ensuring consistency across every technician, job, and location. When crews use paper forms or spreadsheets, it’s nearly impossible to guarantee that every step is completed the same way. One technician might be meticulous, while another might overlook key details.

Inspection software should provide standardized digital templates that make every inspection thorough and uniform. For example, a crane inspection template in crewOS guides technicians through each required step, from checking for fraying on a wire rope to properly documenting an OSHA deficiency, so nothing is skipped. By embedding best practices directly into the workflow, teams gain repeatability and quality control across the board.

The benefits go beyond compliance. Standardization helps reduce liability, supports training for new technicians, and creates confidence for customers who want proof that their equipment is serviced with precision, every time.

2. Real-Time Data Capture in the Field

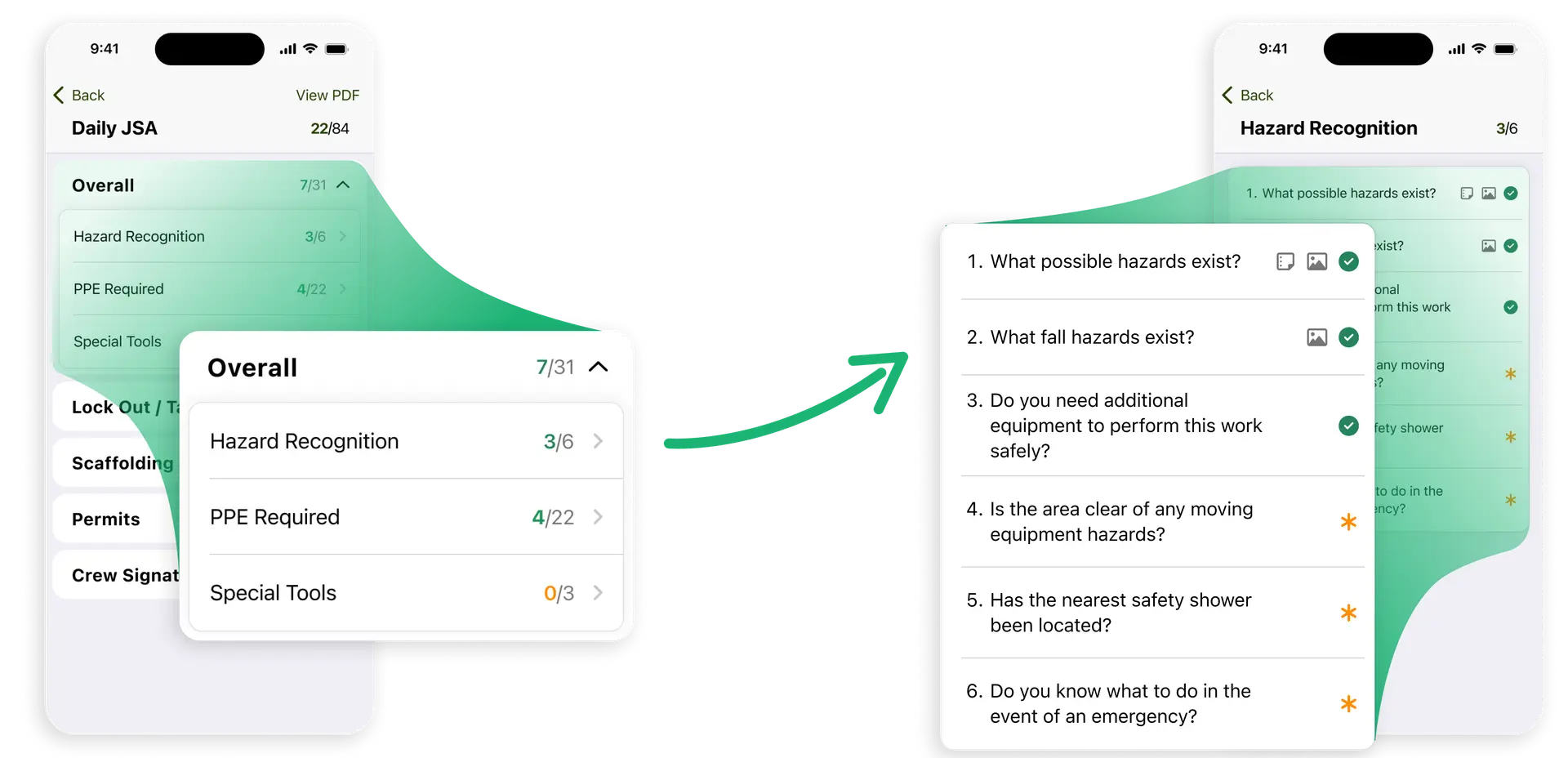

Industrial inspections don’t happen in the office, they happen in the field, often in harsh environments where connectivity isn’t guaranteed. A good inspection platform must empower technicians to capture data in real time, even if they’re offline.

This means being able to snap photos, add notes, flag issues, and complete forms right at the job site. With crewOS, those updates are tied directly to the equipment record and sync automatically when the technician is back online. No more stacks of paper to enter later, no more relying on memory to recreate what happened, and no more risk of missing data.

The impact of real-time data capture is massive:

- Managers can see issues as they arise, not days later.

- Customers get faster, clearer reports of the work being done.

- Safety incidents are reduced because nothing falls through the cracks.

Real-time information provides transparency into the field, ensuring accurate management of crews, jobs, and, ultimately, productivity.

3. Centralized History and Documentation

Another common pain point is scattered records. In many companies, inspection histories live in filing cabinets, email chains, or shared folders. That makes it difficult, and sometimes impossible, to pull a complete history of a piece of equipment when it’s needed for audits, customer questions, or maintenance planning.

Modern inspection software should provide a single, centralized record for each asset, bringing together every inspection, service note, photo, and signature. In crewOS, this is organized into searchable records, where you can instantly answer questions like:

- When was this crane last inspected?

- What deficiencies were found on the last inspection?

- Which technician worked on this hoist last, and what did they repair?

Having this documentation at your fingertips saves hours of manual work and eliminates second-guessing. It also strengthens your credibility. When a customer or auditor asks for proof, you can provide a complete, professional record in seconds.

4. Professional-Grade Reports Customers Can Trust

The final must-have feature is reporting that tells the story clearly. Customers don’t want to receive hand-written forms or fragmented spreadsheets; they want professional, branded reports that summarize inspections in a way that’s easy to understand and act on.

Inspection software should automatically compile field data into polished reports, complete with timestamps, photos, technician notes, and digital signatures. crewOS generates exportable PDF reports that can be shared directly with customers, no formatting required.

This matters because your inspection reports are more than compliance documents. They are a reflection of your professionalism, your transparency, and your value as a service provider. The easier you make it for customers to see what you did, what you found, and what you recommend, the more trust you build.

Why These Features Matter for Industrial Field Service

In an industry where safety and uptime are everything, inspections can’t be left to chance. Without the four capabilities above, companies risk more than inefficiency, they risk safety incidents, regulatory fines, and customer frustration.

- For field crews, having mobile, easy-to-use inspection tools means less paperwork and fewer missed steps.

- For managers, real-time visibility provides control and foresight.

- For your customers, standardized inspections and professional reporting build confidence in the service being delivered.

And for the business as a whole, these features translate directly into fewer errors, stronger compliance, faster billing, and healthier margins.

Moving From Reactive to Proactive

Too often, inspections are treated as reactive paperwork. But when done right, they become proactive intelligence. Standardized templates help detect wear before it becomes a failure. Real-time data capture allows for immediate corrective action. Centralized history creates the foundation for predictive maintenance. And professional reports turn inspections into a trust-building exercise with customers.

That’s the difference between inspection software that simply digitizes paper forms, and inspection software that transforms your operations. crewOS was built for the latter. By putting all your inspection data into one connected platform, we help teams move beyond compliance and turn inspections into a driver of safety, reliability, and growth.

Ready to take your inspection process to the next level?

Let's Connect

We’ll help you gain the edge every field service operation needs.