The start of a new year brings the same questions every industrial field service leader wrestles with:

What equipment do we need more of?

Where are we underutilized?

What’s costing us the most time or the most money?

How do we keep 2026 from looking like every other year of fire drills and last-minute rentals?

Most executives don’t struggle with strategy, they struggle with visibility.

It’s hard to build a solid plan, or make confident capital decisions, when equipment usage is scattered across spreadsheets, whiteboards, text threads, and supervisor memory.

That’s why equipment planning often becomes a guessing game and why companies enter the new year with the same delays, overruns, and avoidable losses.

But 2026 can look very different, and it starts by treating equipment tracking as a strategic data source instead of an afterthought.

The Real Cost of Poor Equipment Visibility

When you step back from the day-to-day, the biggest threats to your margins often come down to equipment blind spots.

1. Over-renting because the equipment you own can’t be located

A lift truck or welding machine that’s sitting idle at the wrong shop is functionally the same as not owning one

2. Underutilized assets eating capital and maintenance budgets

Most companies own more equipment than they actually need, they just can’t see usage patterns clearly enough to confirm it.

3. Delays that start small and end up costing thousands

A misplaced tool or vehicle can push a project into overtime, and overtime compounds quickly during outages or tight shutdown windows.

4. Safety risk from missing documentation or unknown equipment condition

If inspection history lives in multiple places, leaders can’t see which assets are overdue, which are failing, or which should be replaced.

5. Capital planning based on intuition instead of data

Without usage metrics, lifecycle trends, and condition history, budgets become a mix of gut feel and reaction.

This is why the strongest industrial teams are jumping ahead now—not in Q3 of next year—to build equipment strategies powered by real data.

A Strong 2026 Equipment Strategy Starts With Three Questions

Before you look at purchases, replacements, or budgets, leaders need clarity across three areas:

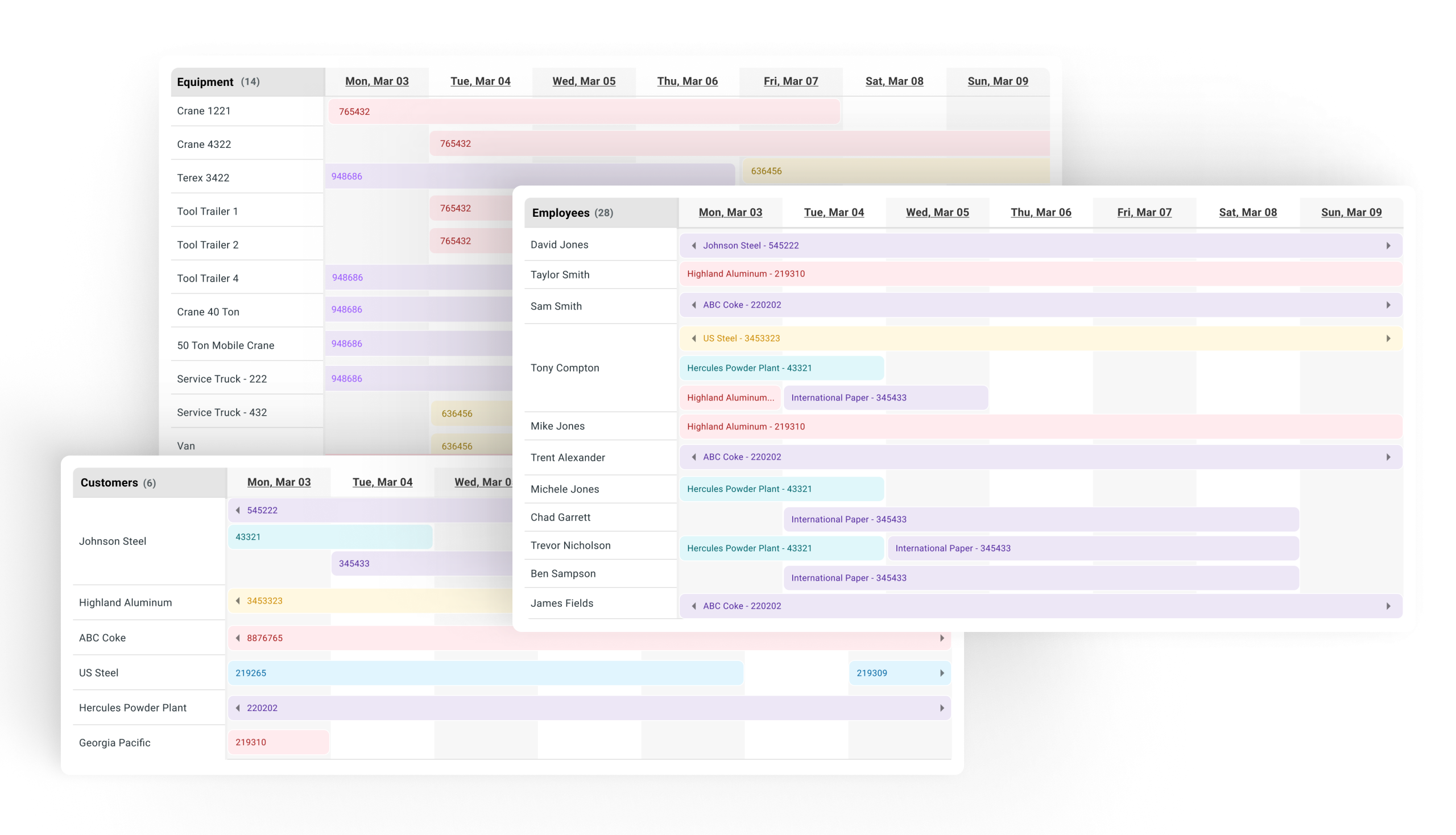

1. What equipment do we actually have?

While it sounds simple, for most companies, it’s the hardest question to answer.

Equipment is spread across shops, trucks, and job sites.

Some sit unused. Some go missing. Some are at the wrong location.

An accurate inventory that is tied to jobs, crews, and locations, is the foundation for everything that comes next.

2. How is it being used?

Not assumed. Not estimated. Not “what we think.”

Actual usage.

Which equipment is:

- Overbooked

- Underutilized

- Frequently transferred

- Breaking down

- Always requested

- Rarely returned

Patterns like these expose where your bottlenecks actually live.

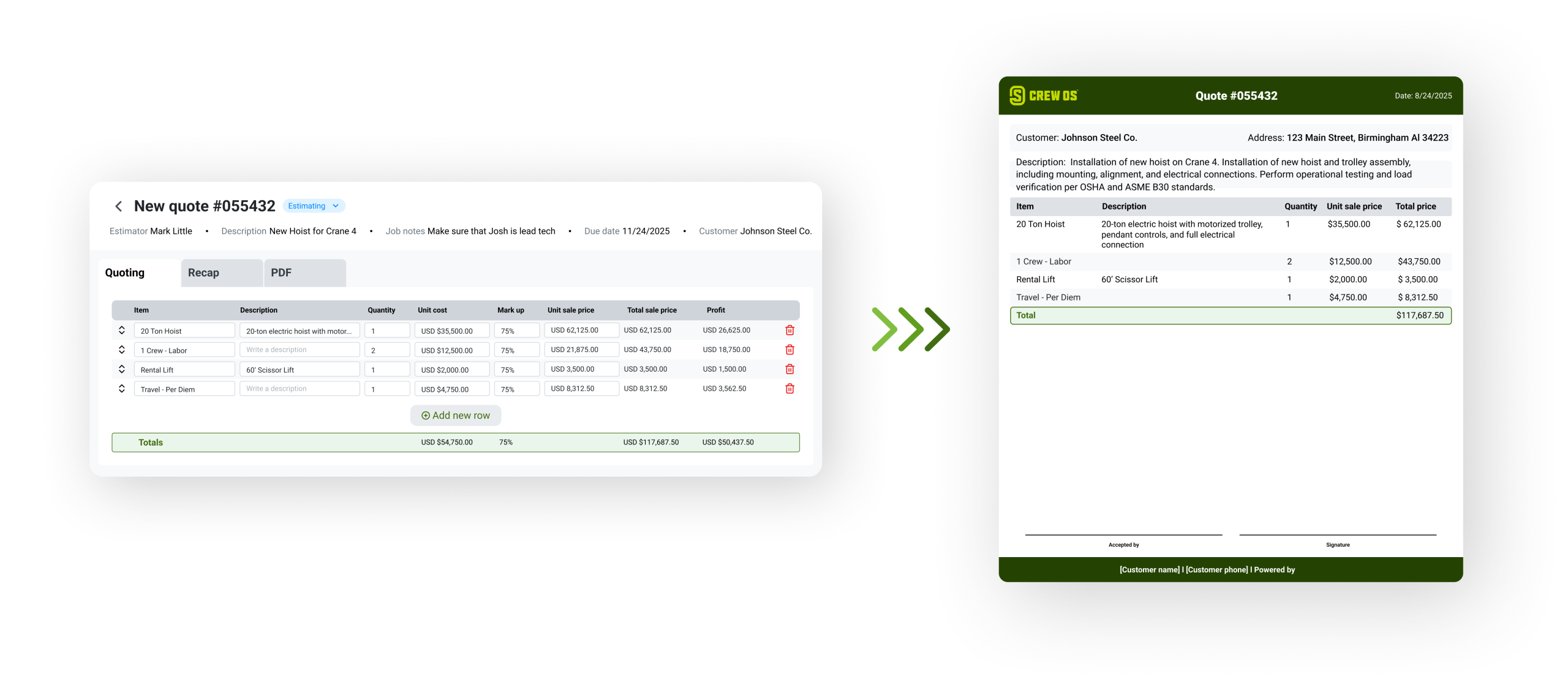

3. What is each asset costing us?

Owning equipment is expensive, and losing visibility costs even more.

To build a smart 2026 strategy, leaders need:

- Maintenance cost history

- Average job usage

- Downtime patterns

- Rental vs. ownership comparisons

- Total lifecycle ROI

This is the level of data that transforms equipment decisions from reactive to strategic.

How Better Equipment Tracking Changes Your 2026 Plan

Once you have accurate, real-time equipment visibility, your planning shifts from reactive to proactive and preventative. For most companies, that shift looks like this:

1. Better Capital Budgeting

Instead of buying “just in case,” you invest based on real usage trends, and stop spending on equipment that sits idle.

2. Fewer Project Delays

Knowing exactly where equipment is means crews don’t lose time searching for tools, waiting on transfers, or improvising solutions.

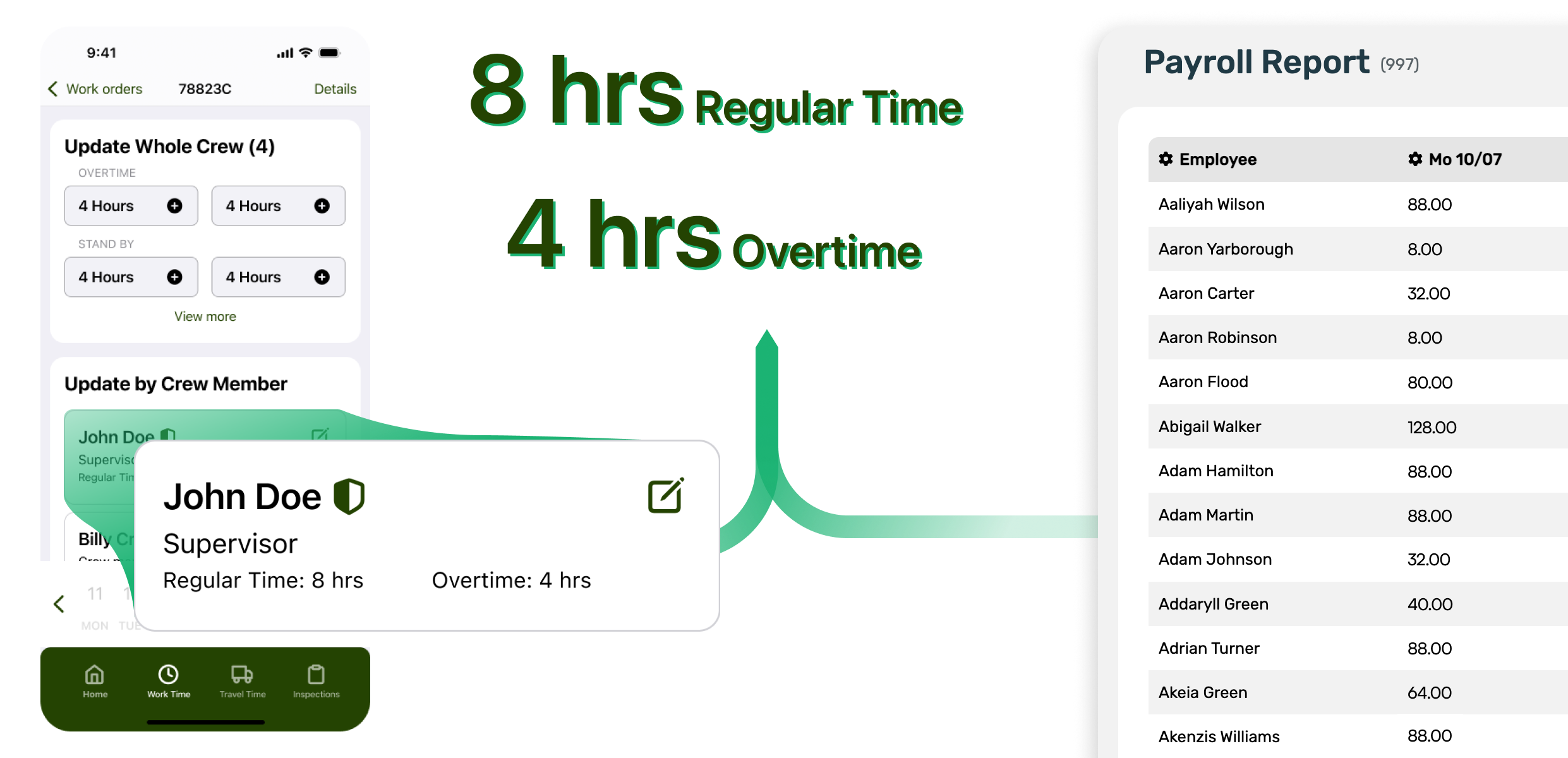

3. More Predictable Labor Costs

When equipment is where it’s supposed to be, crews stay productive and overtime stays under control.

4. Higher Margin Protection

You prevent small losses like missing tools and misplaced gear that quietly erode profitability all year long.

5. Smarter Preventive Maintenance

Real-time histories help you identify failing equipment early, reducing downtime and extending asset life.

6. Stronger Workforce Performance

Crews do better work when the equipment they need is available, safe, and accounted for.

This is how top-performing field service companies build operational resilience going into a new year.

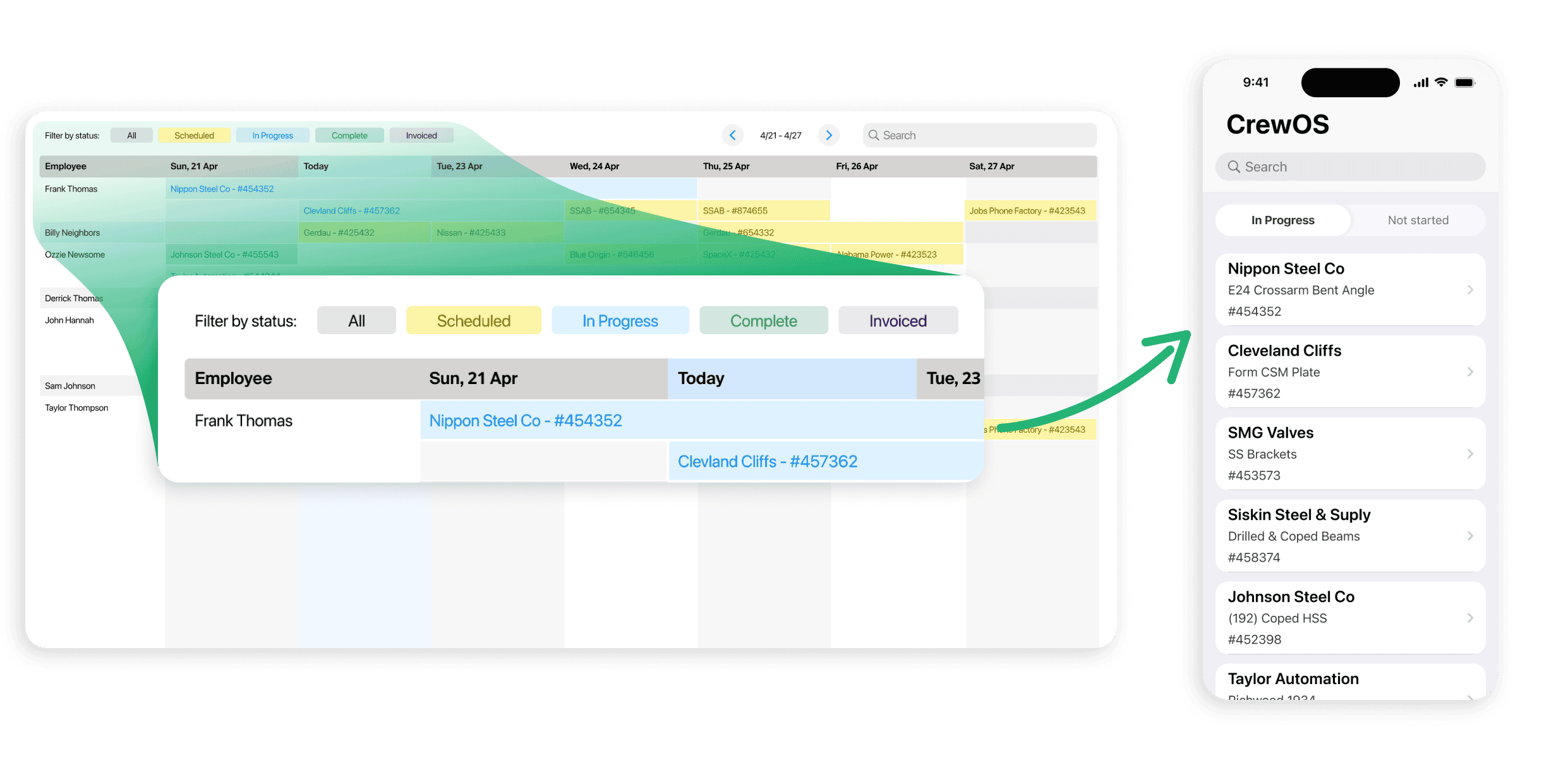

Where crewOS Fits into a Strong 2026 Strategy

The goal isn’t just to track equipment, but to connect equipment data to everything else your teams do.

That’s why modern equipment strategies rely on platforms that:

- Tie equipment directly to jobs

- Track movement in real time

- Capture usage, maintenance, and cost history automatically

- Work offline in plants, steel structures, and remote areas

- Give leadership a live view of every asset

crewOS was built for exactly this.

But more importantly, it was built for companies who want control, visibility, and profitable decision-making going into 2026 and beyond.

When you know what you own, how it’s used, and what it costs, you start the new year ahead, not behind.

–

2026 is coming fast. Ready to make sure your equipment strategy is solid?

Let's Connect

We’ll help you gain the edge every field service operation needs.