In every industrial field service operation, assets are the backbone of the business: cranes, hoists, trucks, fans, pumps, turbines, and more.Having physical equipment is one thing. Understanding what equipment you own, where it is, how it’s performing, and what it costs you is another.

Too often, asset data lives in spreadsheets, paper logs, or disconnected systems that don’t talk to the rest of the operation. That makes it hard to plan work, control costs, and prevent downtime.

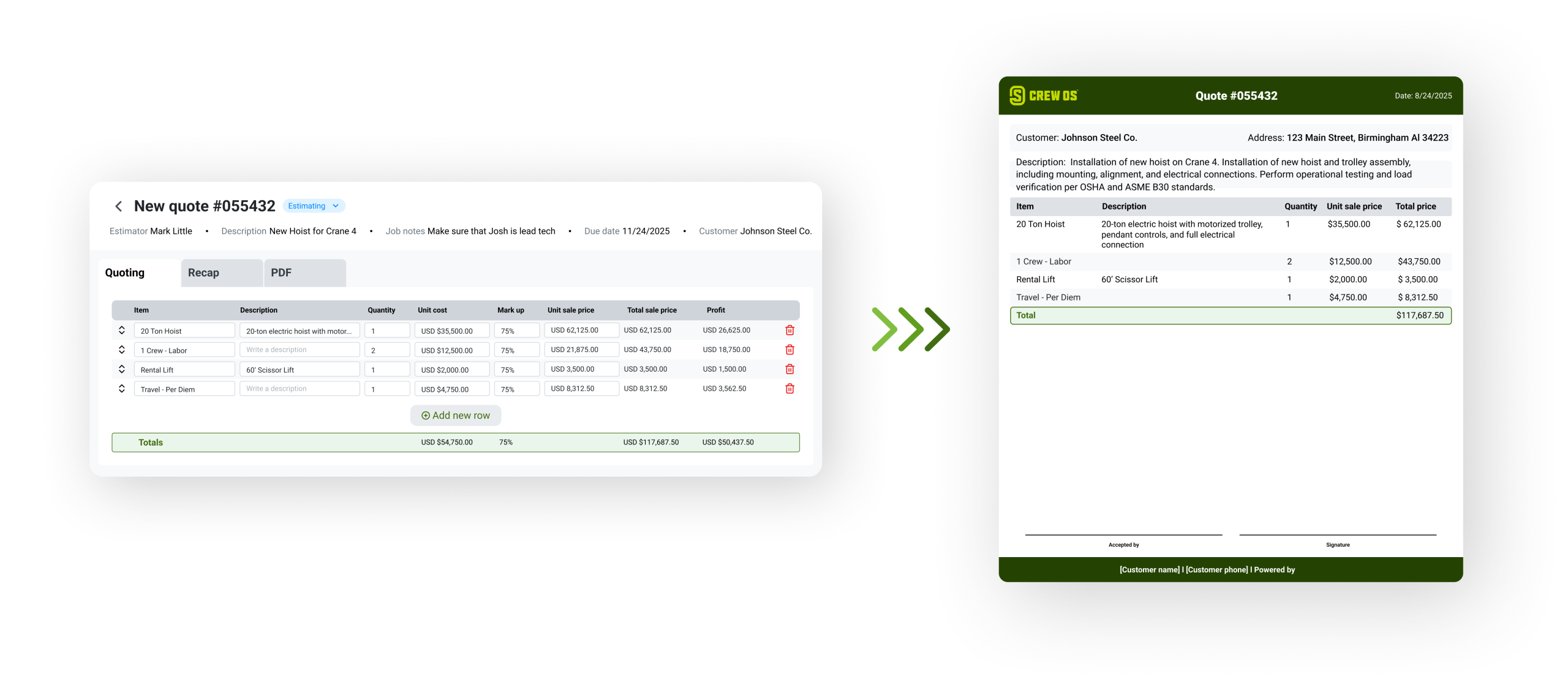

Asset management in crewOS was built differently, not just to track assets, but to connect equipment intelligence to every part of how you manage work. Below, we unpack how intelligent asset management works inside crewOS and why it’s a foundation for smarter field service operations.

The Problem With Traditional Asset Tracking

In many industrial field service organizations, asset tracking starts and ends with a list: description, serial number, last inspection date. This static view can help a little, but it doesn’t provide context.

Common challenges include:

- Spreadsheets that fall out of date the moment a technician moves equipment

- Paper inspection records that never make it to the office

- No link between an asset and the jobs it’s involved in

- A lack of insight into historical performance, parts usage, or failures

Without connected asset intelligence, companies struggle to answer basic questions like:

- Where is this piece of equipment right now?

- When was the last time it was serviced?

- How many times has it failed?

- Which assets are costing us money this quarter?

crewOS solves this by making assets a core operational object instead of an afterthought.

How crewOS Asset Management Solves This

crewOS asset management puts equipment data at the center of your operational workflows. Here’s how it works:

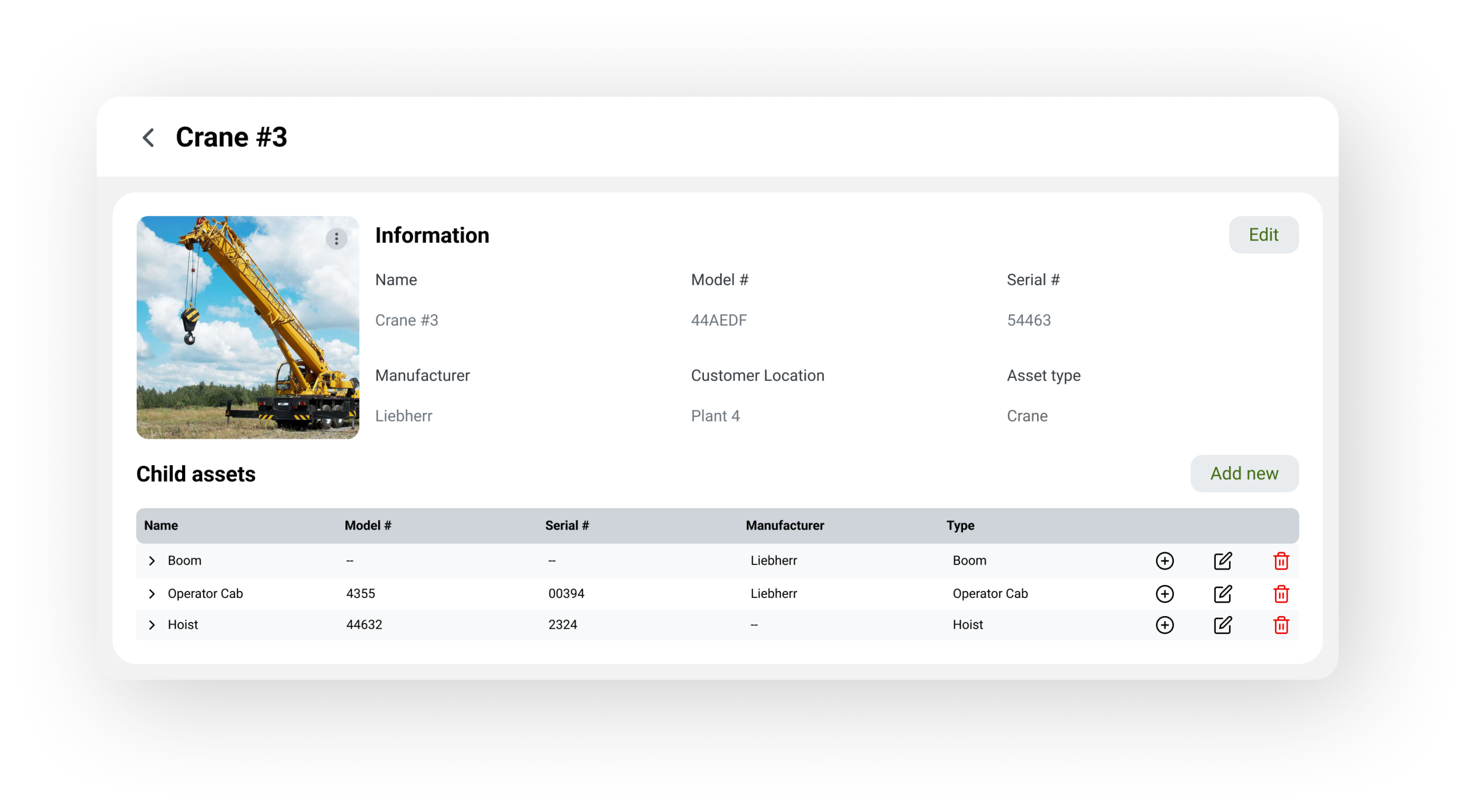

1. Assets Are Structured, Not Static

In crewOS, assets aren’t just items in a list, they’re organized into parent/child hierarchies that reflect real-world configurations. For example:

- Crane → Trolley → Hoist → Wire Rope → Hook

Every component can have its own record, history, and service data, but still remain connected to the larger system it supports.

This structure makes it easy to get a complete picture of an asset and all associated elements, without guessing or cross-referencing files.

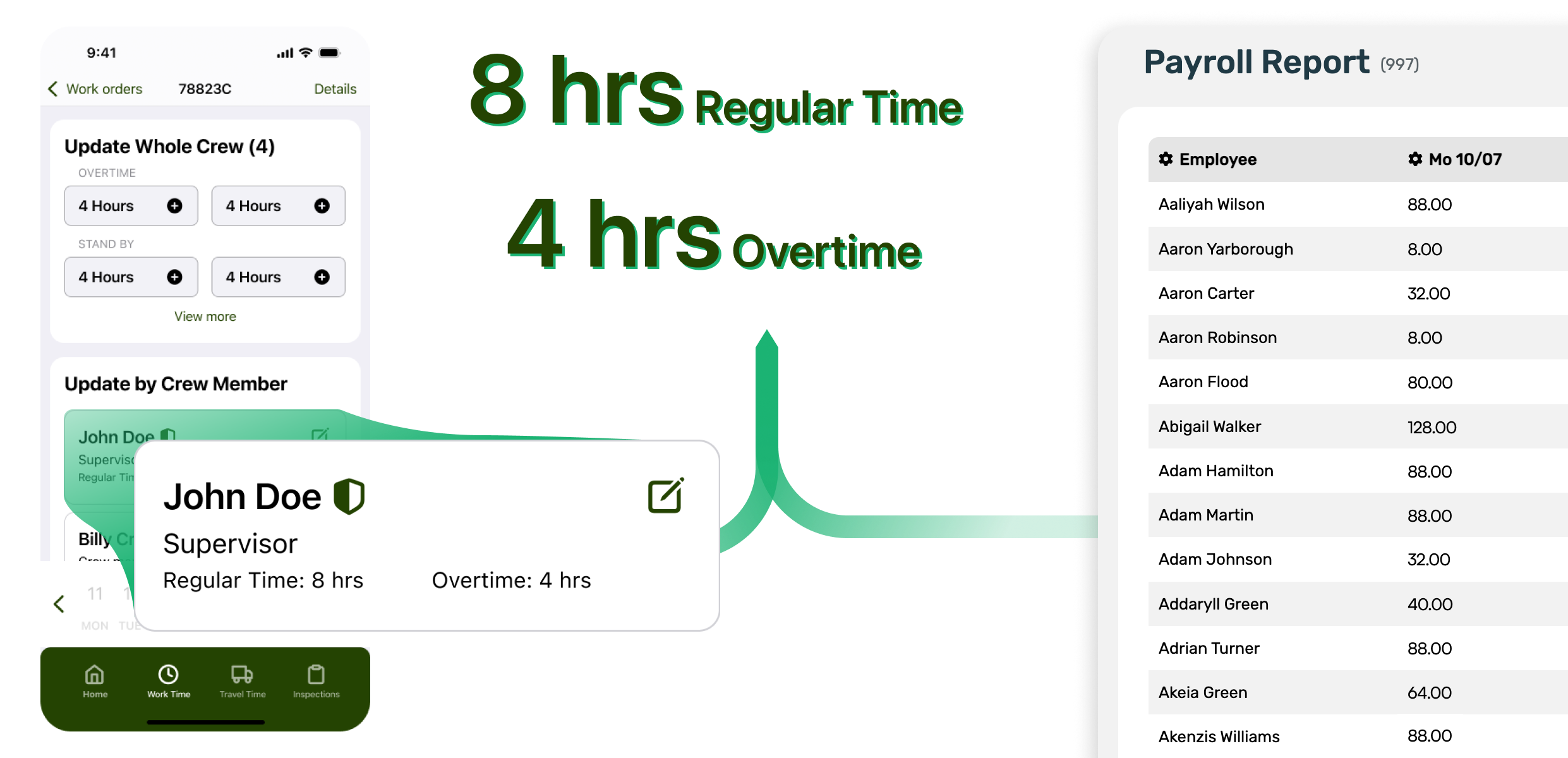

2. Complete History of Inspections, Maintenance, and Work

Every inspection, repair, maintenance task, or note is attached directly to the asset’s record in crewOS.

When a technician:

- Performs an inspection

- Logs a defect

- Replaces a part

- Notes a service observation

that information becomes part of the asset’s history.

No more hunting through emails, paper reports, or separate systems. All related data lives in one place and is instantly accessible.

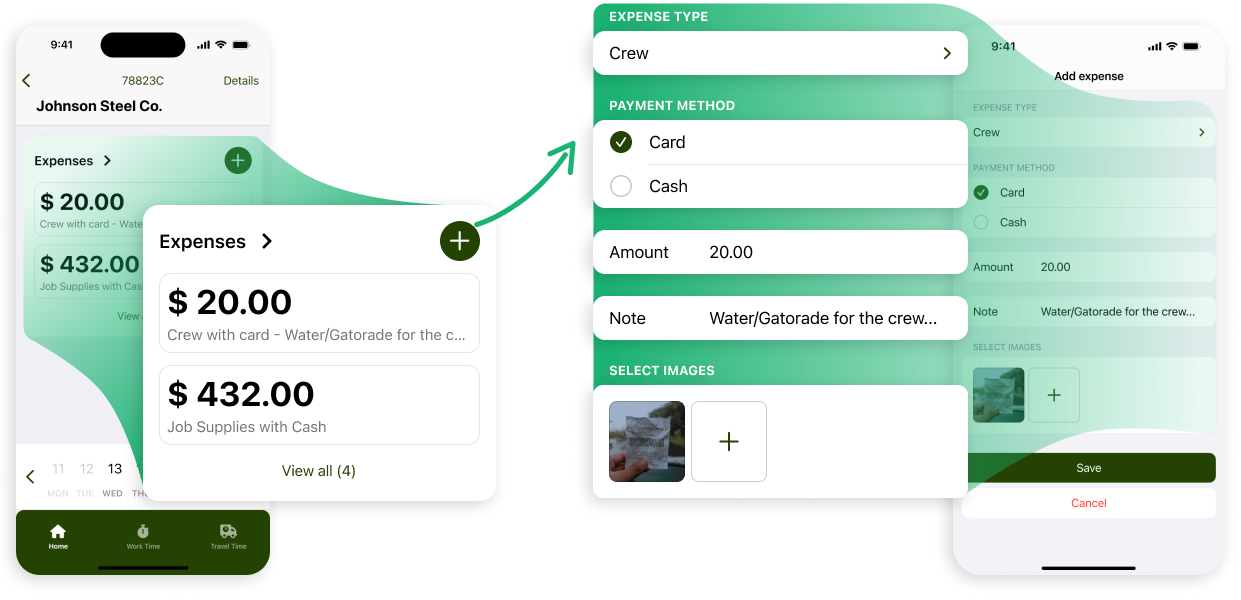

3. Connected to Jobs, Crews, and Costs

An asset in crewOS isn’t isolated from the rest of the operation. Each asset is tied to:

- Work orders where it was inspected or repaired

- Crews who touched it

- Inspection results and photos

- Labor and parts costs

- Billing and reporting workflows

This connected data means you can answer operational questions like:

- Which assets are costing the most to maintain?

- Which assets are frequently involved in jobs?

- Which assets are overdue for service?

- Which assets should be considered for replacement?

That kind of insight helps you protect margins and plan capital decisions with confidence.

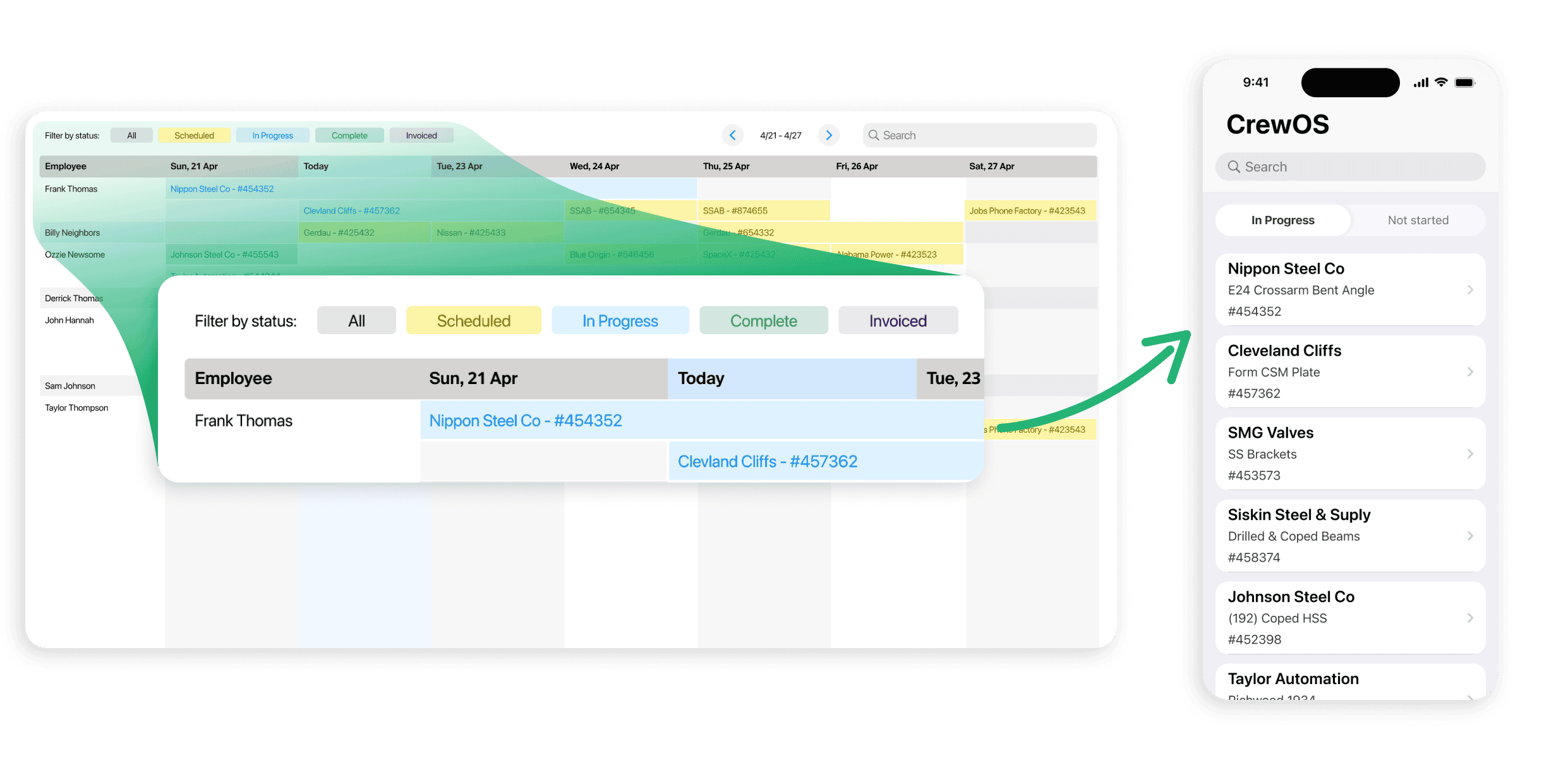

4. Search, Filters, and Quick Access

Asset records in crewOS are searchable and filterable in multiple ways: by tag, location, type, last inspection date, or even issue history.

Need to see all assets that haven’t been inspected in 6 months?

Want to find every job where a specific hoist was involved?

Want a side-by-side comparison of similar assets?

crewOS makes it easy.

Why Industrial Field Service Teams Love Connected Asset Data

When asset management is intelligently integrated, teams experience real operational gains:

Better uptime: Proactively service your customer’s equipment before breakdowns occur

Faster problem resolution: Field crews have complete context at their fingertips

More accurate billing: Asset usage and labor costs flow directly into job costing

Smarter planning: Replace or retire equipment with real performance data

Stronger customer trust: Share accurate histories and service records instantly

In short, Asset Management in crewOS transforms equipment from a silent cost center into a strategic operational asset.

Asset Management is Your Next Competitive Edge

In today’s industrial workflows, data is only as valuable as the actions it enables. When asset data is disconnected, it’s useless. When it’s connected to inspections, work orders, costs, and crews, it becomes clarity that leads to proactive opportunities.

crewOS customers tell us they see this shift first in asset insight, more informed planning, fewer surprises, and a much clearer path to protecting margins.

Ready to bring real intelligence to your equipment?

Let's Connect

We’ll help you gain the edge every field service operation needs.